Sunglass manufacturers are throwing an exciting new eyewear feature into the mix - color enhancing sun lenses - and it’s adding to both function and style. Read why the first-time users respond with 'Wow…..just wow.’

The new color-enhancing advancements make use of color blending sun lenses that go beyond shielding your eyes from glare and harmful UV, to reveal and enhance the world’s true, vivid colors in detail.

In short, these lenses enhance non-harmful colors and illuminate objects much clearer than ever before.

Color-enhancing sunglasses from industry leaders such as Maui Jim are changing the way we see the world by making colors “pop” more than ever before. But are these sunglasses hard to manufacture, expensive, and why aren't you selling them already? We answer all these questions in this blog.

We'll start by asking the most obvious question:

Why Not Just Use Polarized Lenses?

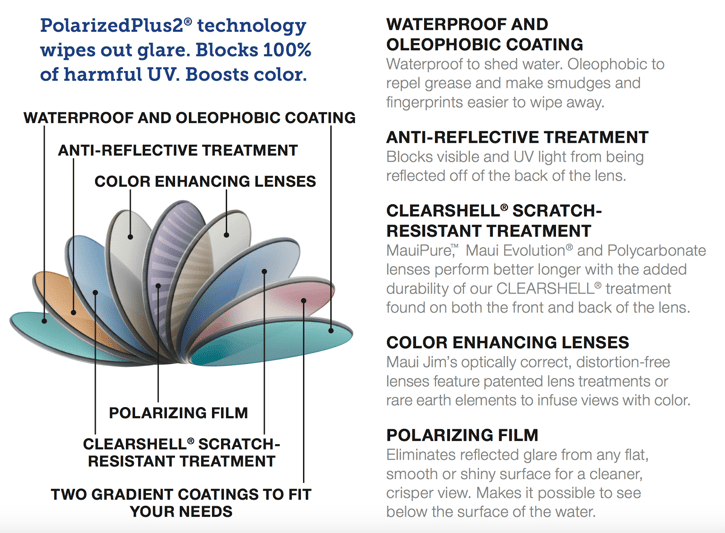

Although the color-enhancing sun lenses use polarization, it’s the combination of coatings, polarization and filter tints that manipulate a variety of bands in the color spectrum, which then affects how we perceive color. Like the new technology from Maui Jim displayed in the image below:

Can You “Feel” the Color?

Different lens colors have always been renowned for the way they make the world “feel.”

This feel is created by combining various elements or oxides used in dyes and coatings that absorb certain colors, and allow others to pass. In a previous blog, we looked at the 6 different color polarized lenses and what each one does.

Where does the color come from?

It all starts in our retina - the color receptors in our retina's are called cones. There are three different types of cones present in the retina, and each one sends a particular range of color information to the brain.

The brain experiences color sensation in a variety of ways which tends to vary slightly from one person to another. When we use various absorbent lens materials to manipulate (or control) these colors, that’s when you get all the “Wow.”

Manufacturers of color-enhancing lenses have to take different surroundings and lifestyle situations into account when producing these lenses. Different lifestyle conditions will require various tints and coatings to accomplish specific goals, and this can’t be achieved with a lucky spin on the Pantone wheel. So let’s look at the different methods currently being used to assure those colors pop.

Pop Goes the Color because the Color Goes…..

I bet that song will be stuck in your head all day now; you’re welcome.

A popular method when using coatings is the use of bandpass filter technology. These coatings reflect all but a specific wavelength of the spectrum through the coating. Bandpass filters transmit light only within a defined spectral band ranging from less than one to many nanometers wide. They are used in a wide variety of applications where spectral isolation is required.

Three critical featured define Bandpass filters:

- Full Width at Half Maximum (FWHM) — the bandwidth at 50% of the maximum transmission

- Center Wavelength (CWL) — the wavelength at the center of the passband

- Peak Transmission (T) — the wavelength of maximum transmission

How does this apply to color-enhancing lenses?

.png?width=300&name=shutterstock_1087071731%20(1).png) Through a combination of precision wavelength control, ultra-steep edges, deep blocking, and transmission levels, you can create color-enhancing sunglasses designed for optimized color performance to fit any scenario.

Through a combination of precision wavelength control, ultra-steep edges, deep blocking, and transmission levels, you can create color-enhancing sunglasses designed for optimized color performance to fit any scenario.

The technology allows for a broader spectrum colors that could be used in selectively promoting or reducing the force of certain colors.

Absorptive dyes can also be used to control certain colors and promote others. A good example of this would be in the use of blue-blocking lenses. Too much blue light exposure can damage the eyes over time and in some cases lead to vision loss.

Blue light stems from using smartphones or tablets, watching TV or even simply going out in the sun.

Blue-blocking lenses have an apparent contrast enhancement due to removing the blue to violet end of the light spectrum. These lenses typically reduce the force of blue light to some degree, but not entirely. Reducing

Canceling out as much blue light as possible is important to eye health, but completely removing blue light can have a detrimental effect on your circadian rhythms, which could lead to sleeping problems. These lenses make certain colors more vivid, so it’s important not to remove all of the blues since this notably changes one's natural perception of color.

Why do some color-enhancing lenses have such high contrast?

.png?width=696&name=shutterstock_1114714661%20(1).png)

Firstly, we need to understand that even though lenses seem to amplify colors, they actually don’t. Similar to any sunglasses, they are designed to reduce the amount of light coming through the lens.

The evident contrast enhancement comes from reducing certain parts of the color spectrum more so than others. The colors being fostered are in the range that the particular cone receptor is most sensitive to, and this is what makes that specific color seem brighter.

It’s evident that these color-enhancing lenses are controlling the spectrum in ways never seen before, and it’s lighting up the world around us. Traditionally these types of glasses were only designed for the colorblind, but this new technology is presenting brand new business opportunities in the eyewear trade.

I Ask Again, Why Not Stick to Polarized Lenses?

Polarized lenses aren’t ideal for every situation. Pilots, for one, aren’t allowed to fly with polarized lenses. Many of the flight instruments and gyros are also polarized in a different direction. Think of the traditional method for testing polarized lenses by looking through them overlapped and at 90 degrees from each other, or by tilting your head sideways. They blacken out nearly all the light, which is exactly what happens to pilots when they try and view their polarized instruments (there’s a Top Gun joke in here somewhere.) A lot of modern cars and trucks also have digital instruments that can cause the same quandary.

Progressive eyewear manufacturers currently developing color-enhancing lenses are addressing this issue head on. By using selective filtering, they can now offer many different options for various situations which open the door to an array of opportunities addressing various lifestyle needs.

Golf is a great example. Most golfers are happy with traditional polarized lenses, but when it comes to picking up their game, they will benefit more from a color-enhancing lens that reduces overall light but enhances green and brown colors to more accurately read the greens. Golfers are even turning to green-enhanced AR glasses to drop their handicap to single digits.

So What’s the Recipe?

.png?width=2560&name=shutterstock_1089978596%20(1).png)

The thing is there’s no silver bullet for success here, the color-enhancing world is your oyster, so to speak. Eyewear manufacturers have differing philosophies on how they approach their sunglass manufacturing options.

One manufacturer might remove more of the yellow spectrum to which the eye is most sensitive, which in turn allows other colors to be more recognizable. While another manufacturer might filter out colors in between the most sensitive to allow more colors to pop out.Then others prefer to balance the intensity of colors for a good presentation of all the colors. In the end, it’s all about the client and how they perceive the colors.

Sunglass manufacturers all have valid theories on what makes for a perfect solution for a particular lifestyle, but ultimately the client’s preference of what “feels” right will take priority. As an eyewear expert, you need to tap into that mindset to grow your business and manufacture the best fitting color-enhancing glasses in the market.

Some Tips to Keep in Mind

As you design the optimum sunglasses for your clients, possibly with the help of your eyewear manufacturer, there are some factors to consider.

- You have to eliminate UV which affects the cornea and crystalline lens by breaking chemical bonds and causes permanent damage to the eyes. The most eyewear of any type has reduced UV, but you need to make sure the eyewear you produce is up to standard.

- Be sure to choose products that lessen the force of HEV (High-Energy Visible) light in the violet-blue range of the spectrum as discussed above. It’s worth noting that some blue light is beneficial and that eliminating too much of it can distort colors.

- Make use of polarization only when it’s appropriate (90% of the time) to reduce glare such found on snow, water or when driving.

- Various filtering tints can be added to reduce the particular wavelength desired to reduce the amount of light as desired by the demographic of those particular glasses. Gradient tints or photochromic lenses are easily done and have the added advantage of allowing a clearer view below with the brighter sunlight reduced at the top.

- Mirror coatings can have the opposite effect and actually reduce light transmittance by reflecting it away from the lens. They will also provide a fashion statement due to the many color options available that many find appealing.

- Anti-reflection coatings should always be used. Seeing as a dark lens is highly reflective, backside coatings eliminate surface reflections from behind.

With technology advancing at the pace it is and manufacturers becoming more savvier with color-enhancing lenses you can drive your eyewear business in the right direction. You can move away from providing just regular eyewear to offering superior eyewear to your clients.