The eyewear supply chain in China is a bit of an enigma and greatly misunderstood. More often than not we don’t consider the intricate networks involved to manufacture eyewear. You need to understand that Manufacturers have suppliers, and those suppliers have sub-suppliers. If you want control the quality and pricing of your eyewear, you need to understand the nature of an eyewear supply chain in China and how you can manage it better.

With buzzwords like trade wars, tariff hikes and rising labour costs in China, why is China still a good option for manufacturing eyewear?

Why China?

Low-Cost Skilled Labor

China might not be inexpensive with labor (anymore), but it’s skilled labor that you need to consider. It’s easy enough to find cheap labor around the world, but there’s no better place to find low-cost skilled labour than in China. The quality of eyewear produced in China has been steadily increasing for years now, not because of improved machinery but because of skilled labor.

Strategically Located

At the heart of the largest industrial location in the world, China is ideally located. Clusters of factories, sub-suppliers and supply routes are well-established and mature. The infrastructure in China competes with any first world country with excellent train systems, modern highways and the largest ports in the world, everything is interconnected. Getting anywhere or anything in China is a non-issue.

Low Raw Material Costs/Evolved Supply Chain Management (Mature Infrastructure)

Years and years of setting up internal and external raw material supply chains, opening and running mines in places like Africa has perfectly positioned China for low-cost raw materials. Don’t confuse low-cost with low quality; the material is as good as any you can find anywhere else given you control the quality from the source.

Access to Cutting-edge Technology

It’s no secret that China can recreate any technology available, but it’s very commonplace to see German, Dutch or US technology in nearly every eyewear factory or laboratory. China knows the value of good machines and good technology and is not scared to spend the money on tech. Do yourself a favour next time you’re on a factory floor and take a look at the origin of the manufacturing equipment.

Cost-Reduction Approaches

Product Design

The more intricate the design the more expensive the eyewear; simple designs cost less. Realistically you can’t expect to get “cheap” manufacturing for complex eyewear and keep up with top-tier quality. Simply put, more complex eyewear designs require more steps in the manufacturing process, which makes it both time consuming and ultimately more expensive. “Simple designs” don’t have to be simple though, and the quality can be as good as any eyewear out there if you manage it accordingly.

If you can’t live without complex designs and a bit of bling bling in your eyewear designs you need to consider product line rationalization.

General Manager Zenobia Chan Presenting at MIDO 2019

Topic:

COST-CUTTING DONE RIGHT THE BUILDING BLOCKS OF AN EYEWEAR SUPPLY CHAIN DESIGNED FOR CHINA

Download Free PDF. version of the presentation HERE

Product Line Rationalization

PLR allows you to focus on the best-selling eyewear with the help of your vendors. Using PLR will enable you to reduce SKU’s and focus on faster selling, more popular models.

The Cambridge Dictionary classifies Product Line Rationalization as:

“The process of reducing the number of products that you sell in order to invest more in the products that make the most profit: The goal of product rationalization is to reach a maximum number of customers with a minimum number of products in order to maximize revenue for each product.”

Lean Product Manufacturing

It’s easy to think “I buy the frames from the factory, lean manufacturing isn’t my responsibility” and you’d be partly right. But, don’t think it doesn’t matter to you! You need to consider lean manufacturing when choosing the best-fit manufacturer for your business model. A lean factory = better-priced eyewear, as simple as that.

In the negotiation stage, you’re much more likely to have better success cutting costs if you’ve looked at a manufacturer’s ability to run lean.

Pull Supply Chain Management

The eyewear trade moves at a fast pace and forecasting what trends and designs will hit the mark with consumers isn’t always easy to get right; you remember the tiny sunglasses phase. There are two approaches to supply chain management: one is “push”, and one is “pull”.

Push supply chain management is when you stock up for the season and carry lots of stock in your warehouse that you then need to sell.

Pull supply chain management is where you manufacture to meet supply and demand.

Instead of forecasting and producing eyewear in large numbers you manufacture the SKU’s that are in high-demand when they’re in demand - keeping your inventory low and in doing so cutting wastage costs of unsold frames.

THE BUILDING BLOCKS OF AN EYEWEAR SUPPLY CHAIN DESIGNED FOR CHINA"

Quality Focus

China isn’t exactly synonymous with quality. Unfortunately, it’s become a bit of a stigma, but China has been doing this for many years and is hitting the mark close to or in the centre now. PEL as an inspection service provider has front row seats in factories in Wenzhou and Shenzhen daily and in the last five years, we’ve seen a significant increase in quality. Especially with new type of eyewear like Blue Light Blocking Glasses hitting the market.

How does quality focus help you?

If you focus on quality and the quality process and internal QMS with your manufacturer(s) you can prevent reworking orders down the line. You can prevent coming to the end of an order and finding out something went pear-shaped which will require an expensive rework. If you work with your factory you can make sure quality gets managed in the entire line.

Quality focus prevents large reworks and delayed launch dates with a proactive approach to maintaining quality during production.

Total Cost Management

A system to analyse the benefits of any given project or product by managing each cost. If you’re not using a total cost management analysis to project costs you need to consider implementing a total cost management system.

Material Cost Focus

There are thousands of eyewear suppliers in China, but we often neglect to look at the sub-suppliers. You have the choice of sourcing the materials for your eyewear designs yourself instead of accepting what your manufacturer offers you outright.

If you really want to cut costs you should go directly to the source of acetate, hinges, screws etc. and speak to the factory directly to reduce cost and ensure quality directly from the source.

Cost Cutting Assessment

There are a few practical points you can consider to reduce the cost of Raw Material, Operational and Manufacturing Costs by asking yourself a few questions.

Raw Material Costs

Do you purchase from the manufacturer’s or are you using central procurement, bulk purchasing for acetate, hinges, screws and the like from the material suppliers?

Operational Cost

Managing orders and quality internally, are you managing this yourself and what does that look like? Do you send staff to China to check quality and manage orders? If so what are the costs related to this i.e. flights, accommodation, insurance etc?

Manufacturing Costs

Is your manufacturer running lean and using Six Sigma properly? Do they use a QMS system to manage internal quality? Do they use central procurement?

How Much Can You Save?

If managed correctly you can save up to 67% on Cost and Time. To explain how let’s look at a case study from one of PEL’s clients:

Factory #1

Looking at the figures above we can see the client had a purchase order quantity of 2100 pieces for 3 x SKU’s. However, they worked with a factory that wasn’t ideal for their business model which resulted in three reworks after two failed QC inspections. The frames ended up costing them Euro 0.3 cents per frame.

Factory #2

The client switched to another, more suitable, manufacturer after proper assessments and after a single QC inspection, the goods were cleared for shipment reducing the cost per frame to Euro 0.1 per frame.

Factoring in the time it took to rework the order after QC inspection failed twice, we can see that by switching to a better-suited manufacturer this company saved 67% on cost and time.

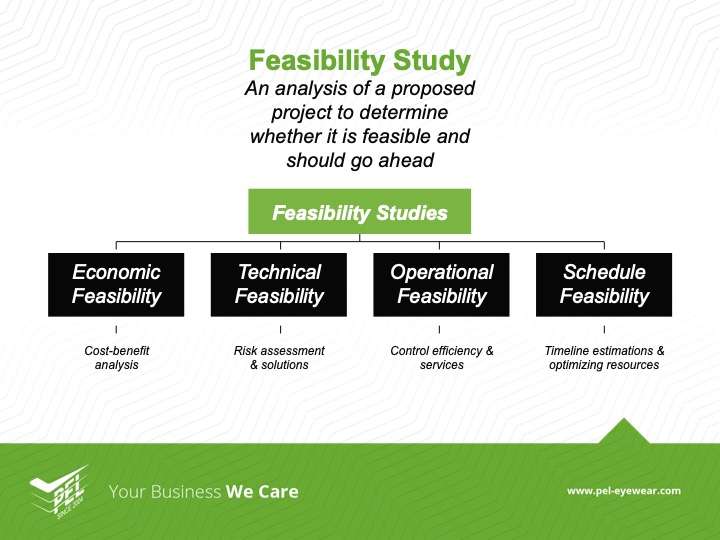

Feasibility Study

As you can see in the diagram above, a feasibility study is an analysis of a proposed project to determine whether it will be feasible and whether you should move forward or let it go. This isn’t only prevalent for China but can be used for other countries like Cambodia and Vietnam as well.

But let’s look at regions in China - Wenzhou, Xiamen, Shenzhen, Chongqing etc.

Economic feasibility - navigating to these regions takes a bit of effort. Even if there are direct flights to the cities you’ll have to make use of high-speed trains, taxis or private vehicles, any of which tend to be a trek. So you’d want to plan your trip well and set aside enough time to cover all bases. The process can be expensive if not done correctly. You can also speak to an expert in the region for some professional advice.

Technical feasibility - is the factory equipped and set up to produce your designs? Is their machinery up to date, good quality and well maintained? What does their raw material procurement process look like?

Operational feasibility - will you be able to control the efficiency of the factory? Even with a rock solid PO and legal points in place, can you afford to waste time with a substandard order, or reworks?

Schedule feasibility - Slightly trickier but you need to figure out how well a factory manages their time? What would a delay look like? Do they have a track record to prove time efficiency? How will your order progress be communicated?

Cost-Saving

To cut costs, safeguard quality and ensure product compliance you must start with the RAW MATERIAL suppliers. As previously mentioned, eyewear manufacturers procure raw materials from various suppliers, and to control your quality you’ll need to make sure those sub-suppliers supply safe, good quality raw materials to your manufacturer.

This is particularly prevalent in the EU when you look at REACH for a list of restricted substances, or FDA regulations in the US.

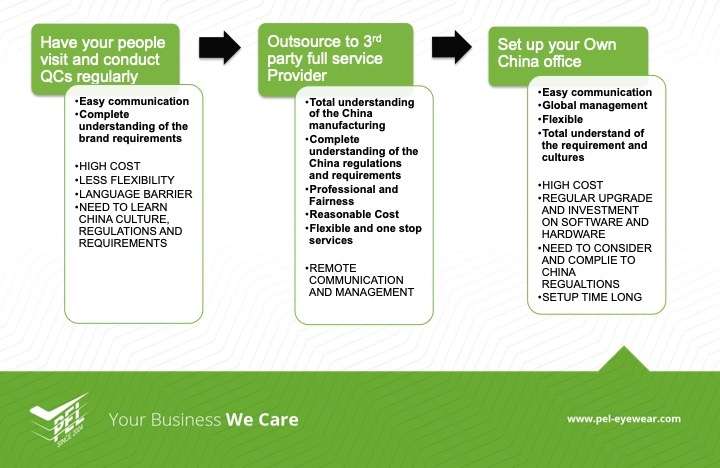

Choices for Cost Reduction

You have to weigh up your options and assess the costs to each approach. Listed below are the three main options to control your supply chain.

1. Send your own employees to China to conduct QC

2. Outsource to a third-party

3. Set up your own office in China

The columns below list both Pros and Cons for each approach:

Cost Comparison

The below figures have been converted from Renminbi to Euro for an easy cost comparison.

The comparison is for a single Purchase Order Quantity of 100,000 for three SKU’s with the three options to compare - using third-party, send own employees to China or setting up an office in China:

Conclusion

There are three tools at your disposal that you can consider using to cut costs in your eyewear supply chain:

-

Audit the factory - covers all the technical aspects of the factory, QMS, social compliance, sub-suppliers etc. if they fall short on any of these aspects move on to the next factory.

-

Inspection - whether you do this yourself or employ a third-party to do your inspection you will be better off notifying the factory from the start. A factory that is aware you will be testing all aspects of the eyewear is usually more cautious with that order.

-

Testing - the only real way to know how safe your eyewear is. You can refer to one of our previous blogs for a complete guide on Restricted & Toxic Substance List in Eyewear - Hidden Dangers (RSL)

Bottom line?

There are better ways to cut cost than bullying your manufacturer.

If you keep squeezing your manufacturer’s to reduce costs but their supply chain isn’t set up in such a way to accommodate you, they will cut corners to give you the discount you’re “forcing” them to. Which will result in substandard materials used to produce your eyewear and higher the risk of unsafe materials finding their way into your products.

Take a hard look at your supply chain and build it from the ground up to cut costs efficiently.

We'd love to hear your thoughts in the comments section below. If you have any questions leave a comment and one of our experts will get back to you soonest.