With the implementation of the EU's Carbon Border Adjustment Mechanism (CBAM) in October 2023, achieving carbon neutrality has shifted from a voluntary commitment to a critical requirement for eyewear manufacturers targeting the European market. This new 'green tariff' initiative highlights the urgent need for brands to balance their carbon emissions with robust offsetting measures, directly impacting their market access and competitiveness.

The Impact of CBAM on Eyewear Manufacturing

Understanding CBAM's Relevance

CBAM aims to level the playing field between European manufacturers and those from non-EU countries who do not face the same carbon costs. By imposing a carbon price on imports based on their carbon content, CBAM ensures that more carbon-intensive products become less competitive in the EU market unless they align with European environmental standards.

What This Means for Eyewear Manufacturers

For eyewear manufacturers, particularly those exporting to the European Union, CBAM necessitates a strategic reassessment of production and supply chain practices.

Manufacturers must now consider the carbon footprint of their entire production process, from the sourcing of raw materials to the manufacturing and transportation of the finished products.

- Cost Management: The direct impact of CBAM is on cost. Eyewear manufacturers might face higher import taxes unless they can prove their products are produced with lower carbon emissions comparable to EU standards. This may require investing in cleaner technologies or sourcing materials from suppliers with verifiable lower carbon footprints.

- Supply Chain Transparency: There will be a greater need for transparency across supply chains. Manufacturers must ensure that their entire supply chain is compliant with CBAM requirements, which could involve more rigorous audits and certifications.

-

Market Positioning: Adopting environmentally friendly practices could not only mitigate potential costs associated with CBAM but also serve as a strong marketing tool. Manufacturers who proactively reduce their carbon footprint can leverage this in marketing campaigns to attract eco-conscious consumers, enhancing brand loyalty and potentially commanding premium pricing.

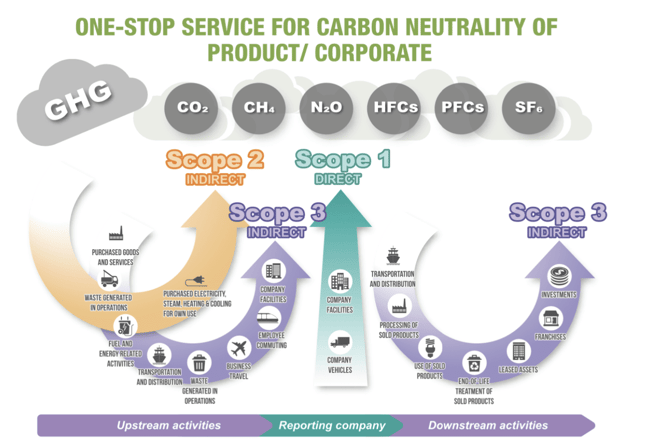

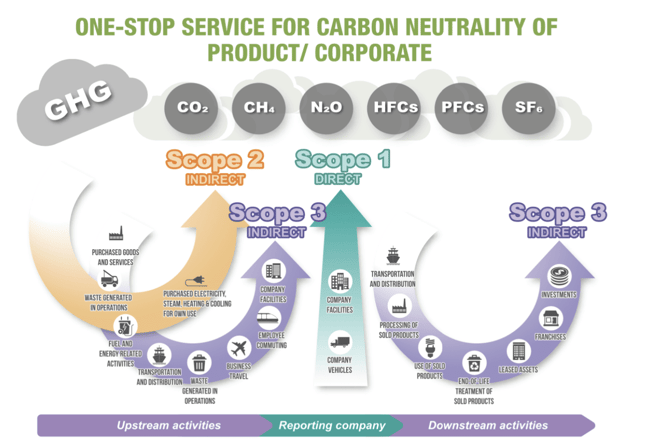

The Scopes of Carbon Emissions of CBAM

The Greenhouse Gas Protocol categorises carbon emissions into three scopes, providing a comprehensive framework for CBAM compliance. For eyewear manufacturers exporting to the European Union, understanding and managing these scopes is key to aligning with CBAM's regulatory demands.

Scope 1: Direct Emissions

Definition and Relevance to CBAM

Direct emissions come from sources owned or controlled by the company, such as company facilities and vehicles. Under CBAM, these direct emissions could directly influence the carbon taxes imposed on eyewear manufacturers. Reducing Scope 1 emissions can mitigate potential CBAM costs and strengthen market competitiveness by showcasing a lower carbon footprint.

Examples in Eyewear Manufacturing

In the eyewear industry, Scope 1 emissions typically arise from:

- Company Facilities: Emissions from the combustion of fossil fuels in equipment such as boilers, furnaces, or machinery used in the production of eyewear. This includes the energy required to heat materials or power production processes.

- Company Vehicles: Emissions from company-owned vehicles used for transporting raw materials, components, or finished products. This includes trucks, delivery vans, and any other vehicles operated by the company.

Typical Direct Emissions Sources

For eyewear manufacturers, direct emissions often come from energy use in production facilities and fuel consumption in logistics. These sources have a direct impact on the company’s carbon footprint and are critical areas for initial emission reduction efforts.

Scope 2: Indirect Emissions from Electricity and Purchased Goods

Definition and Relevance to CBAM

Scope 2 encompasses indirect emissions from the generation of purchased electricity, steam, heating, and cooling that the company consumes. These emissions are associated with the energy used by the company but are produced by external sources.

Examples in Eyewear Manufacturing

For eyewear manufacturers, Scope 2 emissions include:

- Purchased Electricity: Emissions from the electricity consumed in production facilities, offices, and other operations. The impact of these emissions depends on the energy mix of the electricity supplier.

- Purchased Goods and Services: Emissions associated with the procurement of goods and services used in the company's operations. This includes emissions from the production and transport of these goods and services, though they are considered indirect.

- Waste Generated in Operations: Emissions related to the disposal or treatment of waste produced during manufacturing. This includes emissions from waste management processes such as landfilling or incineration.

Reducing Scope 2 Emissions

To manage Scope 2 emissions, eyewear manufacturers can:

- Improve Energy Efficiency: Implement energy-saving measures in production processes and facilities, such as upgrading to energy-efficient machinery and improving building insulation.

- Opt for Renewable Energy: Transition to renewable energy sources such as solar, wind, or hydroelectric power. Companies can also purchase green energy from their suppliers or invest in on-site renewable energy systems to reduce reliance on fossil fuels.

Scope 3: Other Indirect Emissions

Definition and Relevance to CBAM

Scope 3 includes all other indirect emissions that occur in a company's value chain, not covered in Scope 1 or Scope 2. These emissions are often complex to measure and manage due to their extensive scope and involvement of multiple external entities.

Examples in Eyewear Manufacturing

Scope 3 emissions for eyewear manufacturers can include:

- Employee Commuting: Emissions resulting from employees’ travel to and from work. This includes personal vehicle use, public transportation, and any other modes of travel associated with commuting.

- Business Travel: Emissions from travel undertaken by employees for business purposes, such as flights, train journeys, and car rentals.

- Product Distribution: Emissions from the transportation and logistics of raw materials and finished products, including shipping, warehousing, and distribution activities.

- End-of-Life Disposal: Emissions related to the disposal or recycling of eyewear products at the end of their lifecycle. This includes the impact of waste management practices and the potential for recycling or disposal in landfills.

Managing Scope 3 Emissions

Addressing Scope 3 emissions involves working closely with suppliers and partners to enhance their environmental practices, optimising logistics and transportation, and improving product lifecycle management. This broad approach is essential for achieving comprehensive carbon neutrality.

PEL’s One-Stop Solution for Carbon Neutrality

PEL offers a range of services designed to help eyewear brands and eyewear manufacturers achieve carbon neutrality:

1. Carbon Footprint Calculation

PEL provides a thorough approach to measuring emissions across all three scopes. This involves detailed assessments of direct emissions from manufacturing processes, indirect emissions from energy consumption, and other indirect emissions throughout the supply chain. Accurate measurement is the foundation for effective carbon management.

2. Verification Performed Under ISO 14064, ISO 14067 and PAS 2060

Our third-party verification services ensure that our clients' sustainability claims are both transparent and credible, fully compliant with these global benchmarks.

ISO 14064: Greenhouse Gas Emissions Quantification and Reporting

This standard provides a structured framework for quantifying and reporting greenhouse gas emissions. PEL helps companies systematically measure and report emissions at the organisational level, ensuring accuracy and reliability in compliance with global best practices.

ISO 14067: Carbon Footprint of Products

ISO 14067 focuses on the carbon footprint of products, detailing the quantification and reporting requirements. PEL assists clients in accurately calculating and declaring the greenhouse gas emissions associated with their products, ensuring they meet this standard's precise demands for environmental accountability.

PAS 2060: Verification of Carbon Neutrality

PEL supports organisations in achieving and validating carbon neutrality, according to PAS 2060. This includes a comprehensive audit of production processes and carbon management practices to verify that the carbon neutrality claims are substantiated and internationally recognised.

Through these standards, PEL not only ensures compliance but also aids in positioning companies at the forefront of sustainability within their industries.

3. Implementing Reduction Strategies

PEL supports brands in reducing their carbon footprint through innovative strategies. This includes adopting energy-efficient technologies, optimising manufacturing processes to reduce waste, and using sustainable materials. Successful case studies illustrate how these strategies have been applied to achieve significant emission reductions.

4. Offsetting Residual Emissions

For emissions that cannot be eliminated, PEL recommends carbon offset projects. These projects, such as reforestation or renewable energy initiatives, help neutralise the remaining emissions. Offsetting is a key component of achieving overall carbon neutrality.

Taking Action Towards Carbon Neutrality with PEL

For eyewear manufacturers aiming to meet CBAM compliance and brands looking to assess their suppliers’ carbon footprint, PEL offers expert guidance tailored to your specific needs.

Here’s how to start:

- Contact an Expert: Fill out our form to initiate a conversation with one of PEL’s qualified specialists. We understand the unique challenges faced by both manufacturers and brands within the eyewear industry.

- Tailored Strategies: Based on your initial consultation, PEL will develop a customised approach to your carbon management. Whether you’re looking to certify your operations under ISO standards or assess and reduce the carbon footprint across your supply chain, we have the expertise to support your goals

If you have any questions on CBAM or its impact on your supply chain, please feel free to reach out.

.jpg)